WOOD EFFECT KITCHEN UNITS: ELEGANCE AND WARMTH IN THE KITCHEN

Wood is a material that always transmits warmth, cosiness and tradition. Nowadays, a wood effect kitchen matches these sensations with technological evolution, with a steadily increasing number of solutions on the market.

Innovative materials and technologies now make it possible to reproduce a typical wood effect, in terms of both appearance and feel, adding further functionalities and protecting the environment.

HARMONY OF STYLE AND FUNCTIONALITY IN WOOD EFFECT KITCHEN UNITS

The different shades of colour in wood species, their typical grain and characteristic feel make the kitchen immediately cosy and convivial.

The wood effect was once reserved for classical kitchens or those designed to reproduce the atmosphere of a mountain dwelling, but over the years, through country and industrial chic styling, it has become increasingly popular for modern kitchens.

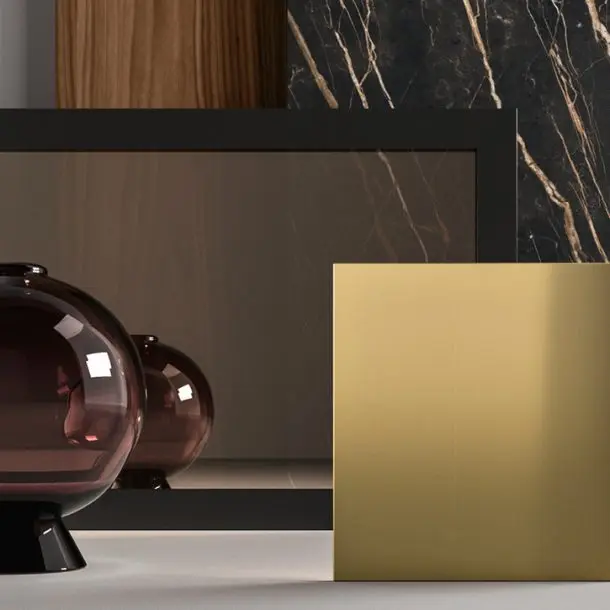

The natural texture of wood is now frequently used in contemporary kitchens, often matched with materials such as steel, resin and quartz.

This is because solutions for creating a wood effect kitchen are constantly evolving, providing the opportunity to combine aesthetics with excellent performance in terms of practicality and safety. Furthermore, an increasingly wider selection of wood effect finishes gives designers even more freedom to combine different elements and styles.

INNOVATIVE MATERIALS FOR A REALISTIC WOOD EFFECT

Nowadays any wood effect can be reproduced in detail, thanks to ever-evolving materials and technologies. Some of the most popular ‘artificial’ solutions for recreating a perfect wood effect are certainly melamine, HPL laminate and Alkorcell®.

- Melamine

Resistant and versatile, melamine is able to reproduce a perfect wood effect, and is one of the favorite materials for kitchen units, above all in vertical applications such as doors for base units, wall units and tall units. - HPL Laminates

HPL laminates reproduce practically any finish or wood effect. With their high performance in terms of quality, resistance and durability, they are particularly suitable for kitchen worktops. - Alkorcell®

Non-toxic and eco-compatible, Alkorcell® plastic coating is applied to an MDF backing to provide durability and hygiene. Gentili Cucine proposes this solution in the three shades of White Ash, Ash and Blond.

All these materials guarantee stunning good looks and ensure great resistance to sunlight and humidity, durability and easy cleaning and maintenance.

They are generally more economical than solid wood, weigh less for the same thickness and provide a practically infinite choice of shades and finishes.

There are other solutions for a truly ‘natural’ wood effect kitchen, made possible by special production methods and treatments for raw materials, like veneering, lacquering or recycling of reclaimed wood.

- Lacquering

Lacquering consists of coating a wood panel with polyurethane paint. It makes the panel stronger, more resistant and easier to clean and the ‘open pore’ version leaves the grain of the wood visible for an attractive natural look. - Veneering

Veneering is achieved by covering an ordinary wood panel with a slim sheet of quality wood (veneer). This gives an outstanding visible surface in wood (e.g. Oak) while saving on costs and reducing impact on the environment. - Reclaimed Wood

Wood reclaimed from fallen trees, ancient beams and floorboards are treated and reconditioned to ensure watertightness and easy maintenance. This produces elements that are naturally unique and exclusive.

WOOD EFFECT KITCHEN UNITS: CONTEMPORARY TRENDS AND STYLES

As we mentioned above, one of the biggest advantages of solutions that create a wood effect in the kitchen is the incredible choice of shades, finishes and species available on the market.

We find endless shades and nuances, as well as the most classical species such as Oak, Ash, Walnut and Fir. The wood effect in vogue at the moment is the evergreen knotted, which exalts the natural knots and grain of wood, while ribbed and flamed finishes are becoming more and more popular.

The ribbed finish is obtained by making a series of regular grooves on the wood surface, usually vertical, which creates a three-dimensional effect that gives movement to the surface through the play of light and shade.

The flamed finish is achieved by a traditional method of burning the surface of the wood. The panel is then cooled, dried, brushed and finished with natural oil. This treatment makes the panels watertight, resistant and extremely attractive.

The password for contemporary design is ‘mix and match’. Nowadays we don’t often see a 100% wood effect kitchen, whereas it’s common to find combinations of different materials.

As an example, wheat coloured ribbed veneer appears next to PET, Laminam and steel, as in our model Time 04 2023.

In the same way, Ribbed Veneered Oak matches perfectly with Itaca Stratified and Nichel Metal Lacquered, as in composition Time 02 2023.